Description

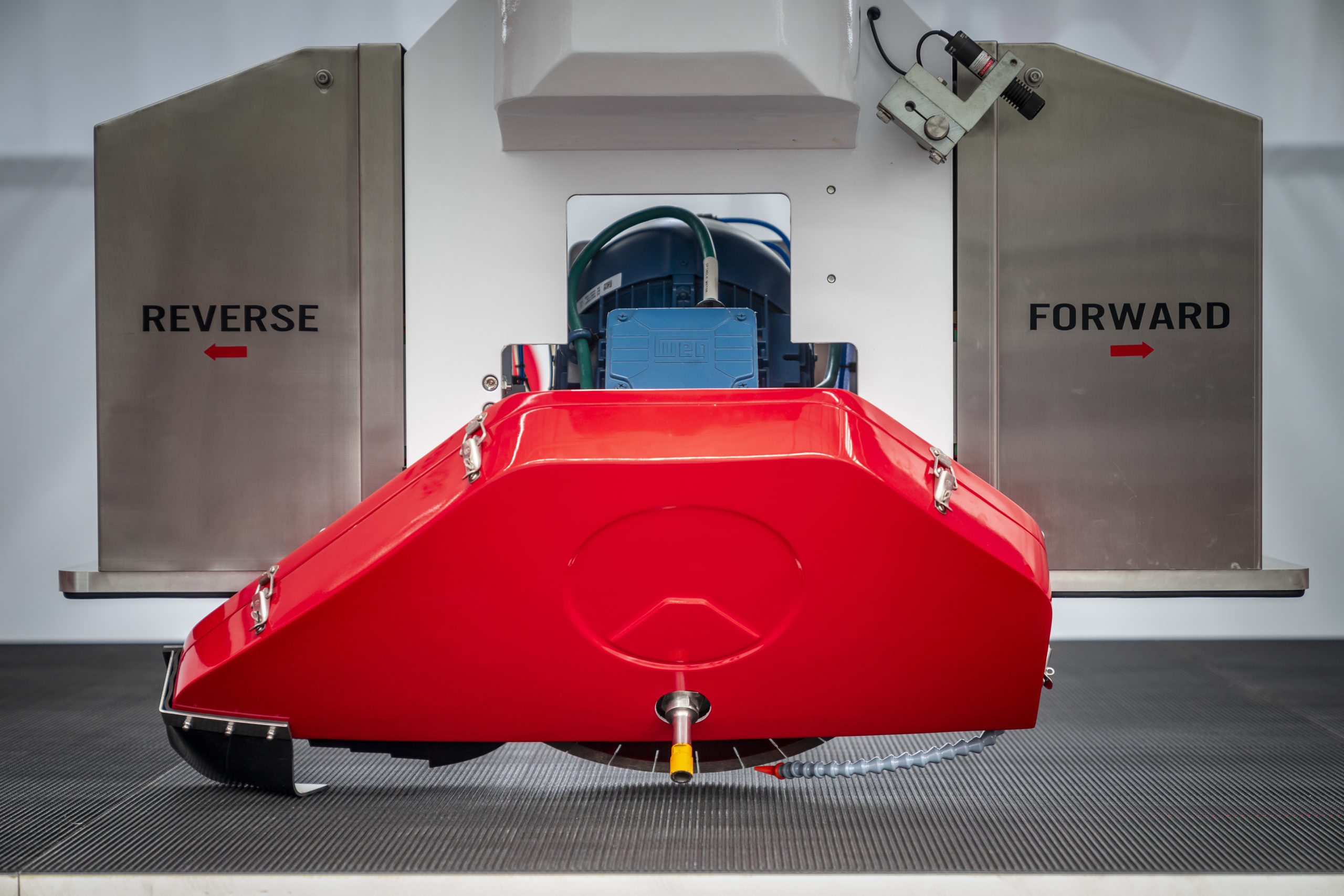

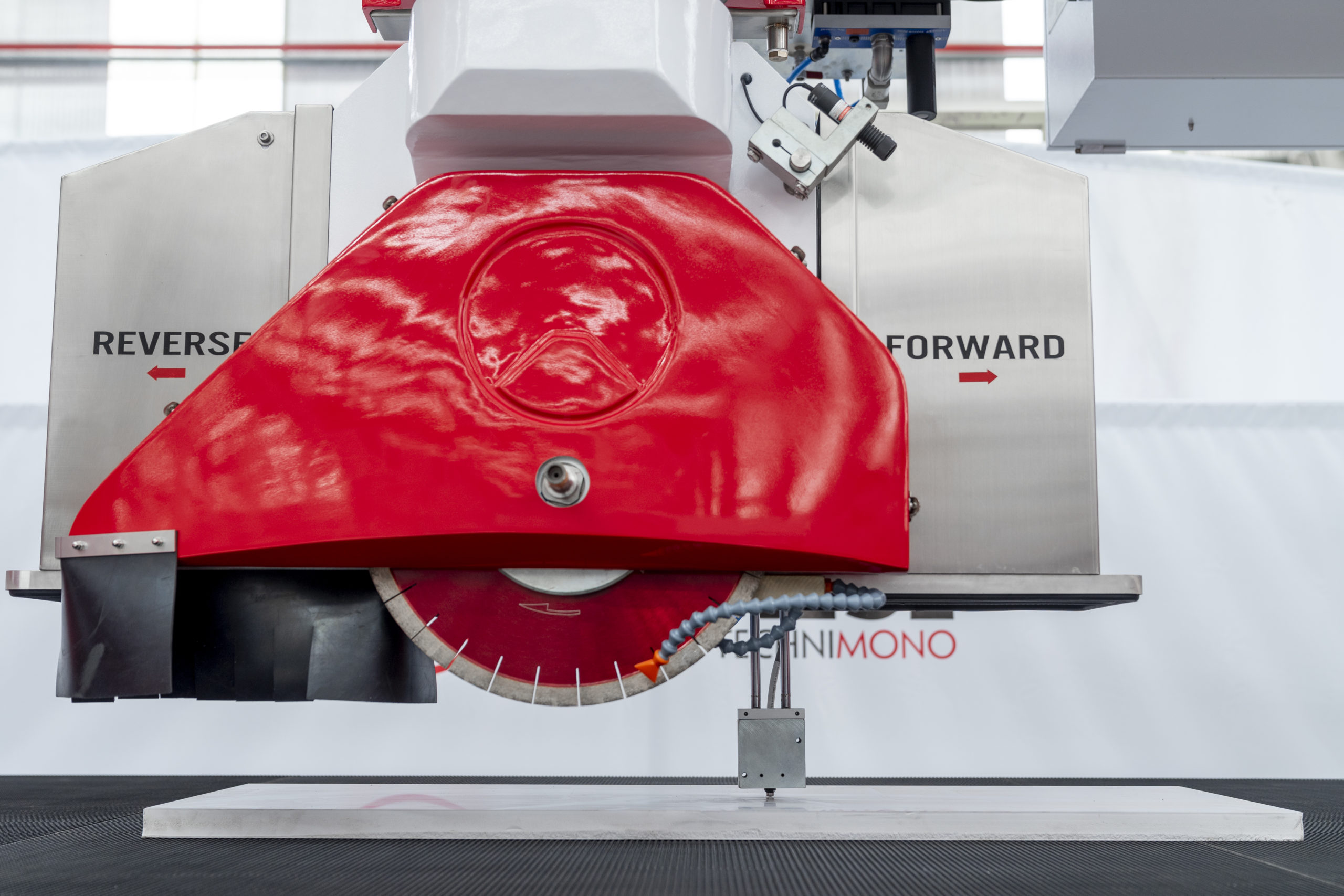

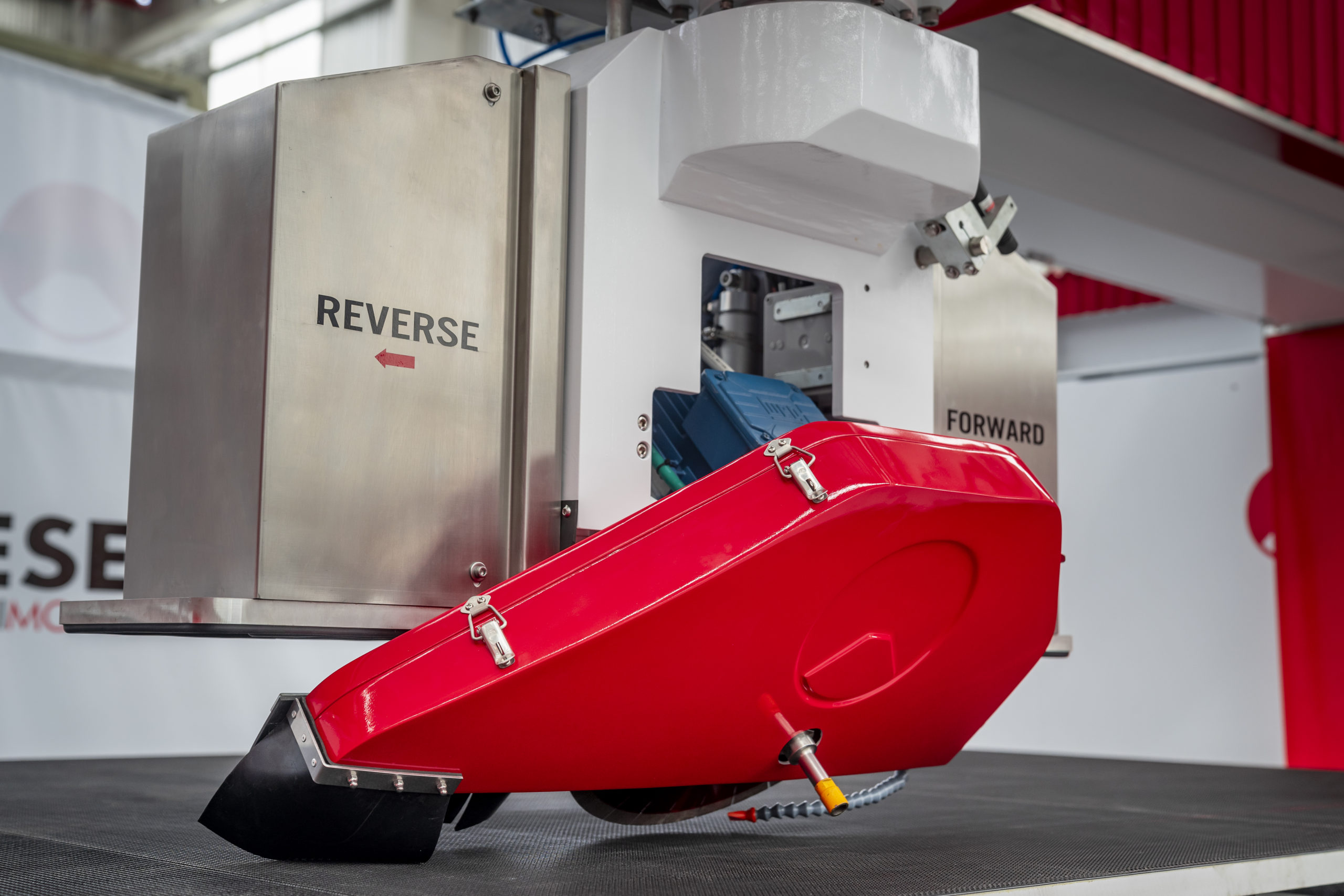

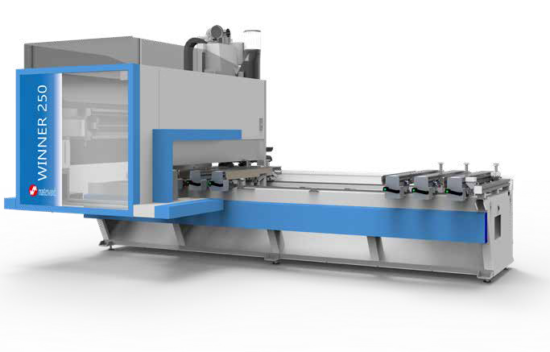

Even though it is a full CNC controlled 5 axis machine, the operator can still use the machine manually as if it was a simple standard bridge saw. The machine is fitted with a separate pendant station that allows the operator movement in order to use the machine for quick manual cuts. It can also work in a Semi-Automatic Program in which the operator can quickly and easily program all the cuts in the X and Y axis allowing for quick trimming and rectangle production. The CAD/CAM system supplied with the machine allows any 2D shapes to be produced including vacuum moves.

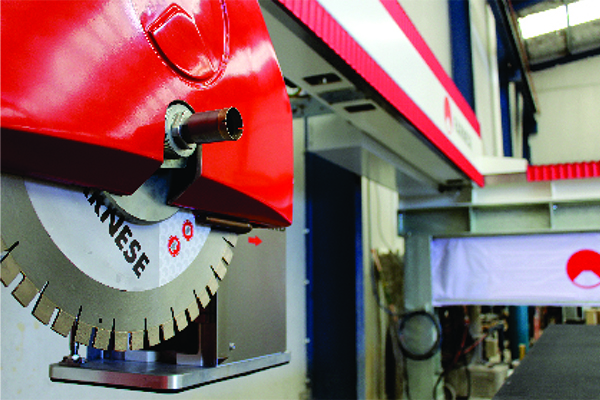

You can also perform simple or complicated cuts using the vacuum manipulator whenever you have blind or curved cuts. The spindle has a 1/2″ GAS attachment that allows to fit a drill. This feature can be programmed to drill out the corners of internal cut outs for easy removal of the internal piece.

With the ability to connect directly to the internet it is possible to log into the machine remotely from our office to help trouble shoot any issue provide further online training.