Description

MAIN FEATURES

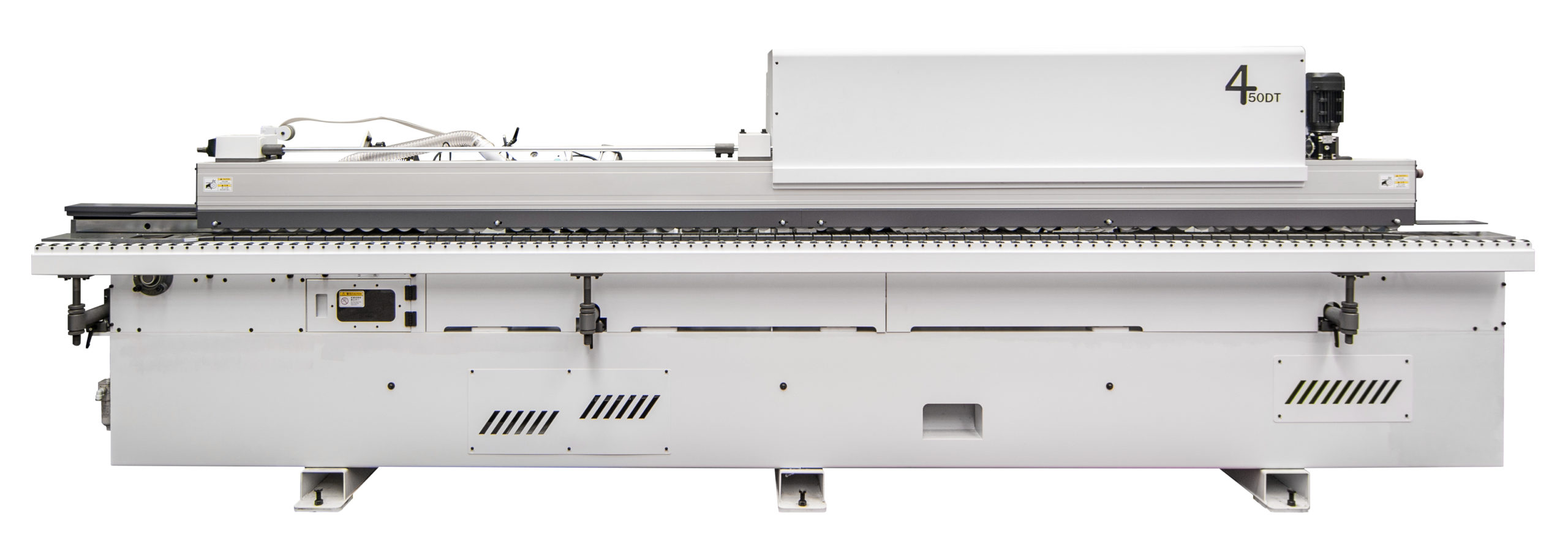

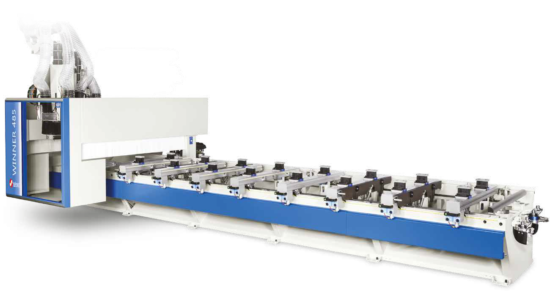

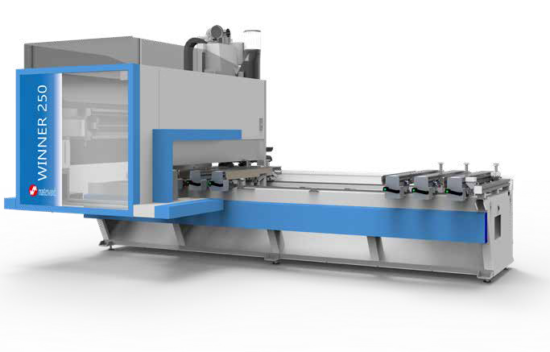

• Machine structure in ribbed electrically welded steel, to grant high rigidity.

• The machine has a compact design, is versatile and user friendly.

• Extensible panel support with roller for large-sized panels.

• Built-in electrical cabinet with main switch.

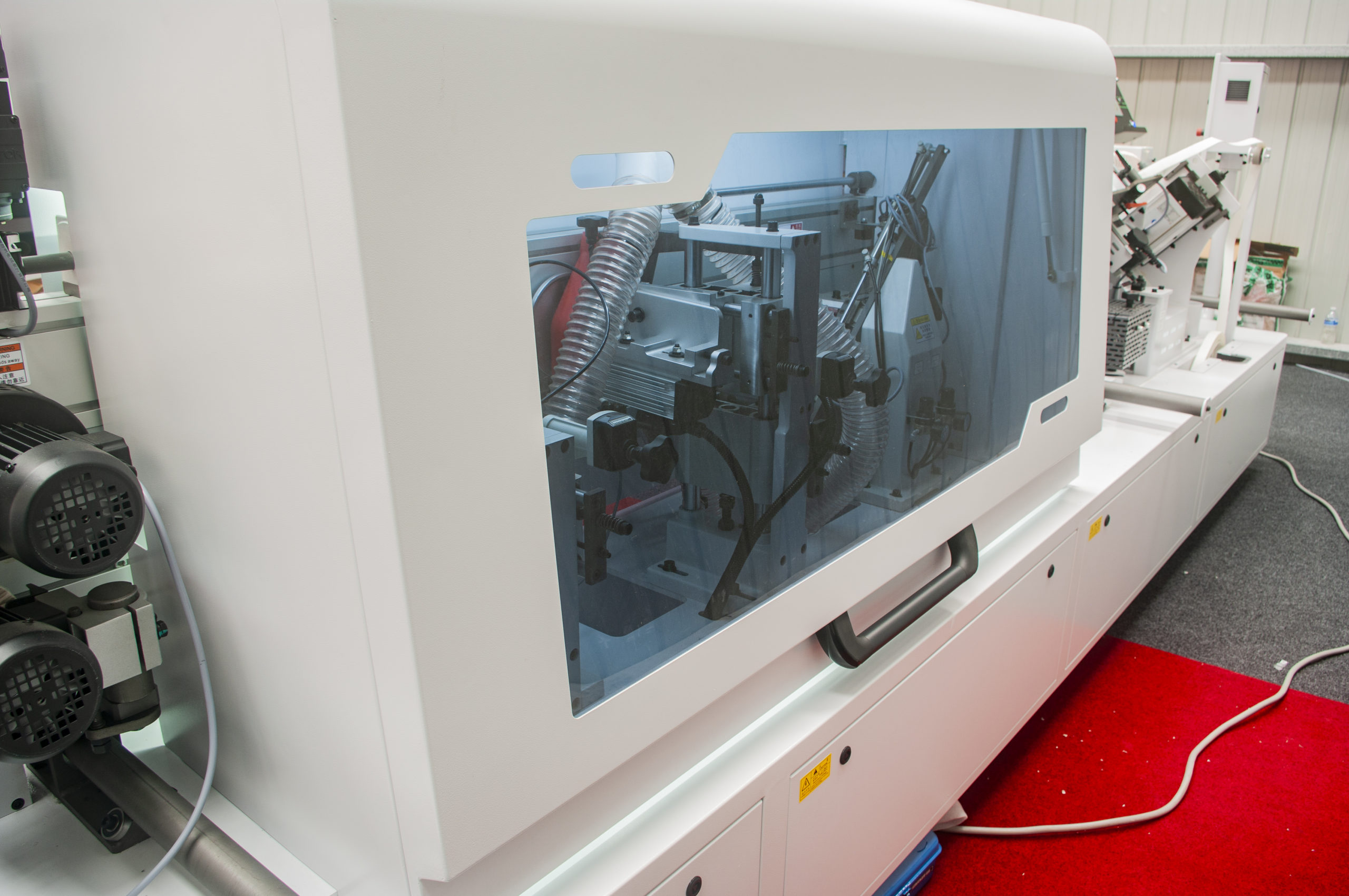

• All working units are protected by a cabin with wide opening allowing excellent view of

the inner parts.

• Machine input and output emergency mushroom buttons.

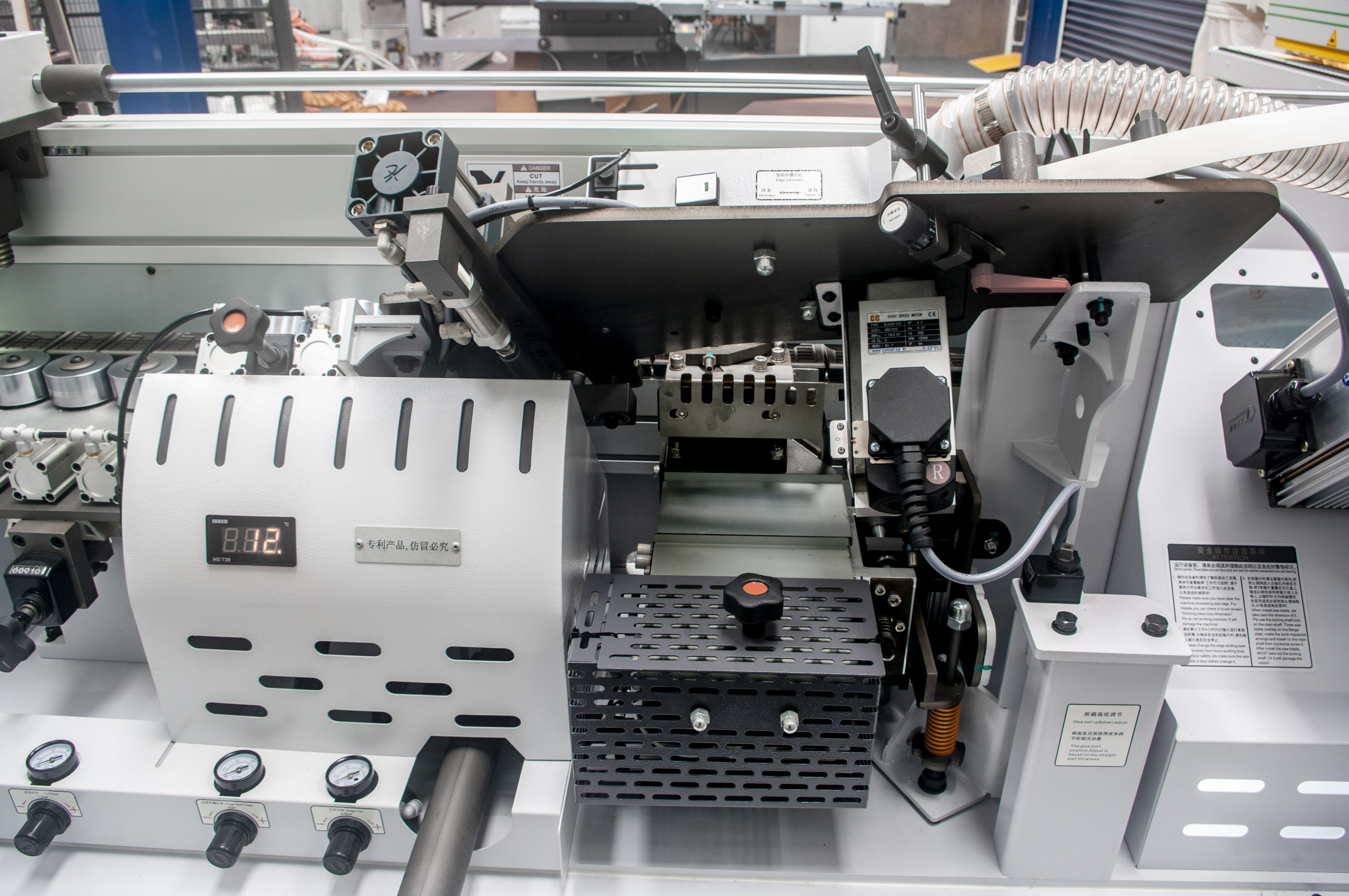

• All motors turn at 12,000 RPM and are controlled by an inverter of suitable power

according to machine configuration.

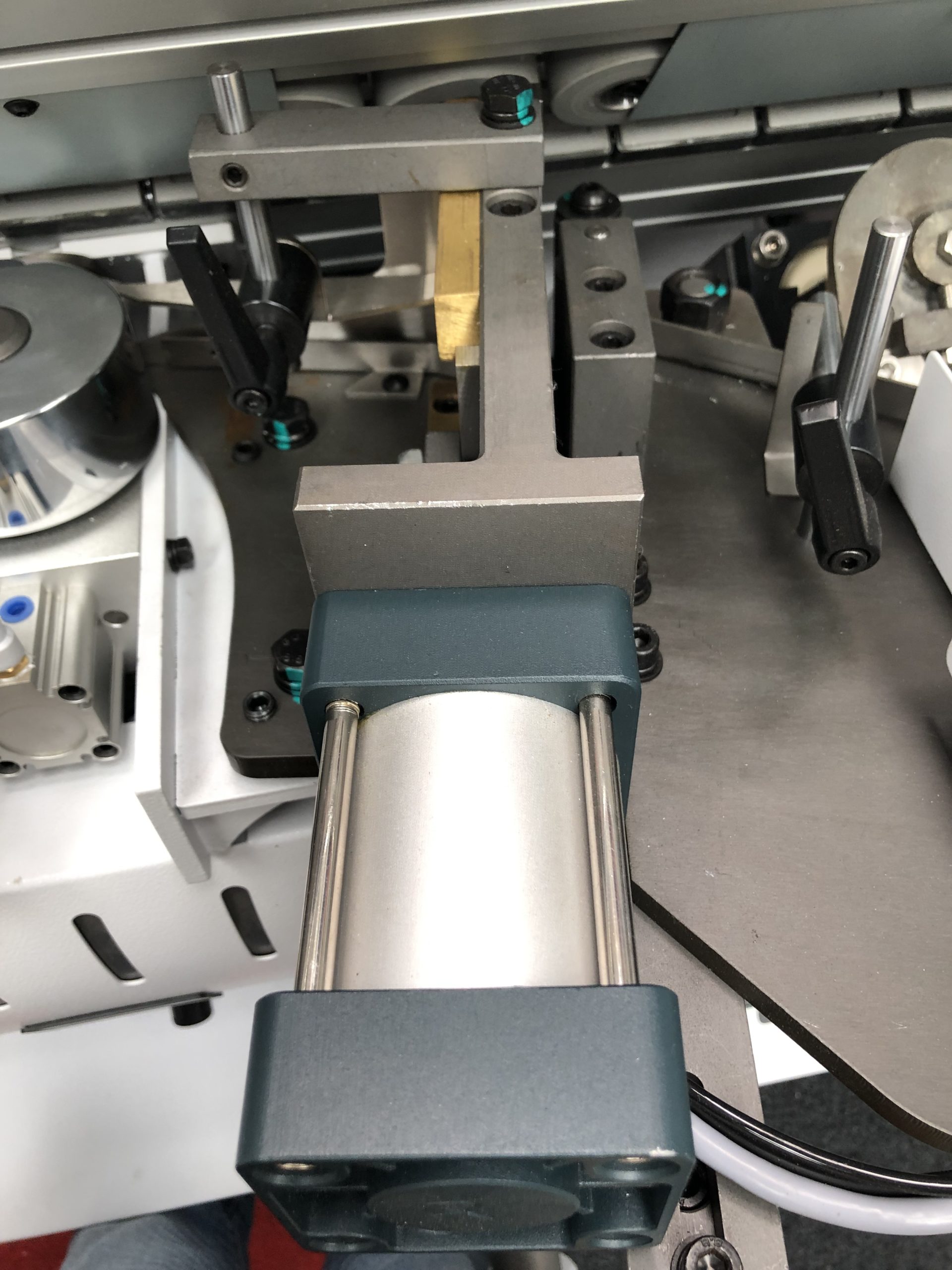

PANEL CONVEYING SYSTEM

• Track movement is made by a robust chain, by means a proper power, orthogonal

geared motor, feed rate 12 m/min.

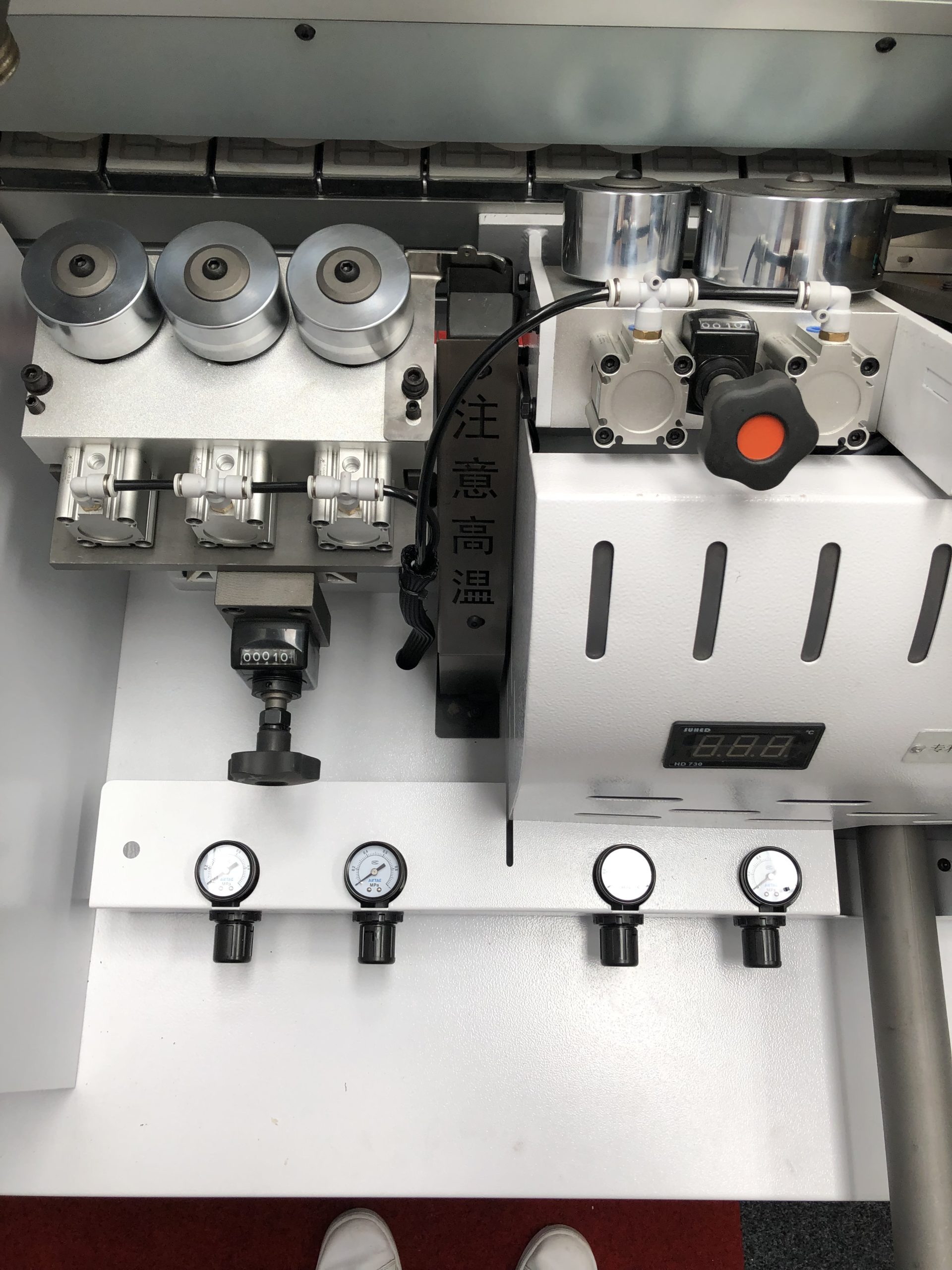

• High coefficient of friction rubber-coated pads are fitted on the chain in order to grant

maximum panel adherence;

• Steel upper pressure beam with double row of wheels

• A track guide with flat round profile is fitted along the upper beam to obtain maximum

precision and straightness even with loadings from the side.

CONTROL PANEL

• The control panel is placed in a very convenient and functional position. Color touch

screen and start and operating controls.

• Control of the machine and of the related units is made by an electronic control;

• On the PLC display the following data are displayed:

– feed rate,

– glue tank temperature,

– program type selected by the operator

MAIN FUNCTIONS

• Loading of roll edging up to 3 mm thick with revolving coil holder plate 0 – 800 mm.

• PVC/ABS shear up to 3 mm.

• The glue tank is teflon-coated to allow easy cleaning and replacing of the glue; it is

equipped with heating elements with adapt power.

• Loading of the roll edging up to 3 mm thick with revolving coil holder (0 – 800 mm) .